SPARCOM: Bringing Frequency Combs to the Final Frontier

SPARCOM: Bringing Frequency Combs to the Final Frontier

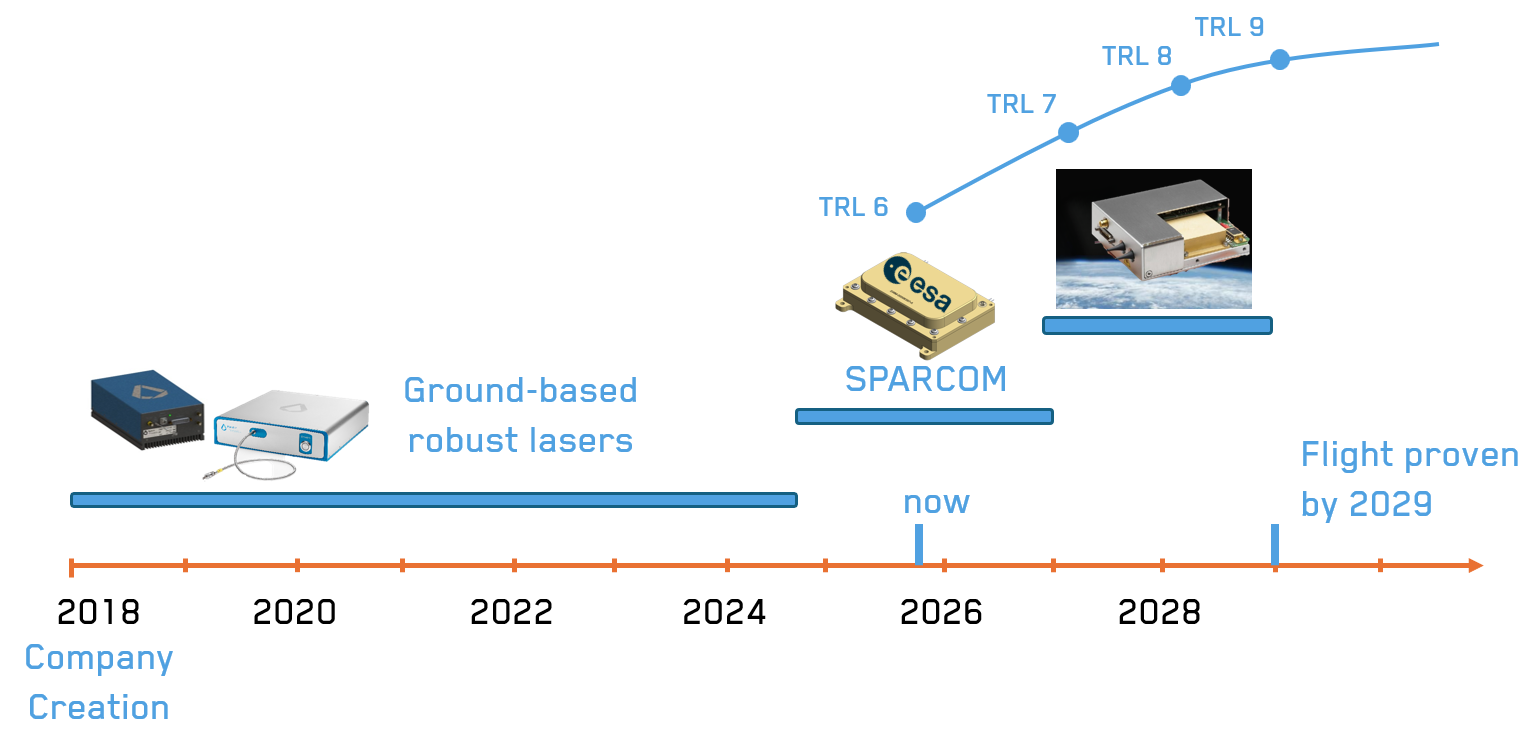

Menhir Photonics manufactures ultra-fast frequency combs that have proven their reliability with already over 6 years of continuous 24/7 operation in ground-based applications. A frequency comb is an optical device that acts like a highly precise ruler for light, enabling the most accurate measurements of time and distance possible.

Menhir Photonics’ solid-state laser cavities are inherently sensitive atmospheric conditions (air pressure changes and humidity) affecting the repetition rate of the laser. While current the dust sealed cavity have already proven its strengths, the company wants to go further. To enable these lasers to work anywhere in the world, in planes and in space, the laser cavity needs to be fully sealed. This is complex because it requires precision mechanics at the nanometer scale while ensuring optical and electrical throughput.

This challenge is the focus of SPARCOM, the ESA-funded SPace Ruggedized Mode-locked Comb project. Maria Milanova (pictured) joined Menhir Photonics just over a year ago to lead this effort, combining mechanical design expertise with project management to turn the vision into flight-ready hardware.

The project’s target is TRL 6, a full-scale technology demonstration in a representative spacecraft environment. “TRL 6 is the highest technology readiness level we can demonstrate with ground-based environmental testing, so this is an important commercial milestone for Menhir Photonics,” Maria explains. For the space industry, that distinction makes all the difference: a system at TRL 6 is qualified, proven, and ready for integration. “The next logical step will be in-orbit demonstration on-board a suitable mission.”

Redesigning for Reliability: The No-Compromise Approach

Now, halfway through the two-year project (2024-2026), Maria is designing a hermetic laser package that can survive the unforgiving environment of space while managing the complex dance of internal development and external collaboration. “I’m digging into the detailed mechanical design work, which is my background,” she explains. “as well as managing the whole project. The work presents exciting technical challenges and I’m learning a lot.”

The project timeline is ambitious but achievable. The team is now moving through hermetic package design, building qualification units through the first half of 2026, and conducting a full environmental test campaign by September 2026. ” SPARCOM encompasses two main parts: the development of a new ruggedized laser casing and a comprehensive environmental testing campaign.” Maria states. By the project’s end, Menhir Photonics will have proven space-qualified frequency comb technology ready for next-generation satellite missions.

At the heart of SPARCOM is a complete reimagining of how Menhir Photonics packages its 2.5 GHz frequency comb laser. “It’s a redesign of the optical module part of our lasers, specifically to make it more robust, more reliable, and hermetic,” Maria explains. A hermetic seal is implemented to protect the delicate optical and electronic components from the vacuum of space, while keeping an inert and constant atmosphere for the laser cavity.

But hermeticity alone isn’t enough. The design must also achieve structural integrity, strain-free laser mounting, including thermal management, as well as the challenge of getting signals in and out while maintaining a hermetic seal. “We’re implementing fully hermetic optical and electrical feedthroughs, using low outgassing materials and space-qualified parts wherever possible,” Maria lists. “The package interior has to be both pressure insensitive and thermally stable, designed with process reliability and product longevity in mind.”

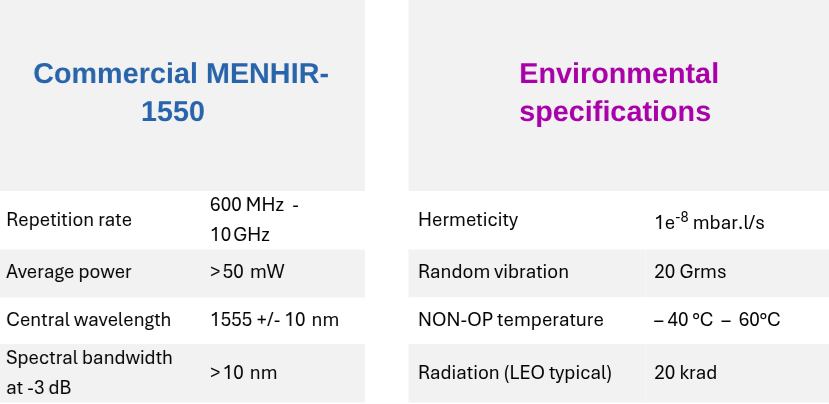

It’s a specification list that reflects Menhir Photonics’ broader engineering philosophy: simplicity enables reliability, and reliability enables scale. While SPARCOM focuses on the 2.5 GHz laser, the same package design will eventually serve applications from 600 MHz to 10 GHz, creating a qualified platform that can address multiple market segments.

The laser package (overall dimensions of 120 x 80 x 30 mm) has been developed and manufactured in partnership with Optical Fiber Packaging Ltd.

Testing to (Almost) Destruction: The Qualification Campaign

The second major part of SPARCOM is undergoing standard aerospace qualification testing, a systematic campaign to prove the hardware can survive everything space will throw at it.

Maria describes the test sequence methodologically: “The laser will be tested both for survival and for operation in space: this includes random vibration, shock, thermal vacuum (TV) cycling, irradiation and leak testing followed by final functional testing.”

Each test simulates a specific threat:

Launch and shock vibration testing subjects the package to 20 Grms of overall random vibration (across the 20 Hz – 2000 Hz range) as well as 1000 G of mechanical shock.

Thermal vacuum cycling is perhaps the most grueling test. The package is placed in a vacuum chamber and cycled repeatedly between the temperature extremes it will face in orbit: -40 °C to 60 °C for non-operating conditions and operational tests where the laser performance will be closely monitored.

The Helium leak test will put the newly designed detachable indium hermetic seal before and after thermal vacuum cycling. The specification calls for hermeticity to 1 x 10 -8 mbar.l/s. Such leak rate is needed to ensure stable inner atmosphere and, thus, stable laser operation for over 10 years. However, preliminary prototype testing on the package has already shown hermeticity beyond this value.

Radiation testing exposes the system to a typical Low Earth Orbit dose of 20 kilorads, ensuring components won’t degrade over the mission lifetime.

The company isn’t starting from zero; earlier tests have validated key design elements. “Building upon previous successful vibration and thermal-vacuum tests, SPARCOM is poised to attain TRL 6 space readiness by 2026,” Maria confirms.

Applications: From PNT to Atomic Clocks

So, what exactly will these space-qualified frequency combs enable? Maria points to PNT (Positioning, Navigation, and Timing) systems as the primary application.

The capability for space applications is compelling. “A ruggedized MENHIR-1550 frequency comb can be used as a high-accuracy clock or as a source for ultra-low noise microwave and radio frequency signals without the need for synchronization to an external source or even GPS.”

Strategic Partnerships within Industry: Leveraging Complementary Expertise

The collaboration with CSEM S.A. is a key element of SPARCOM’s structure. CSEM brings year-long experience on space projects to the partnership. “They are a key player in the Swiss space sector with a strong heritage of technological innovation” Maria notes. This expertise complements Menhir Photonics’ laser technology and manufacturing capabilities, creating a partnership where each organization contributes what it does best.

Beyond SPARCOM: Building for Tomorrow’s Missions

As the project progresses through 2025 and into 2026, Maria remains focused on the immediate milestones: completing the hermetic package design and successfully completing the Critical Design Review (CDR), followed by building the qualification laser units and conducting the environmental test campaign. In the long-term, Menhir Photonics will launch its laser technology to space aboard a suitable mission by 2029.

“In summary, this project’s main goal is to increase reliability through robust design and process optimization,” Maria says, distilling SPARCOM’s essence to a single objective. And reliability, as Beni Rudin has emphasized repeatedly, is what Menhir Photonics does best. “From the beginning, our lasers were really reliable, and slowly but surely we gained the trust of the customers…” For a company that started seven years ago with the goal of bringing ultra-fast photonics from the laboratory to the industrial scale, it’s a remarkable milestone.

Anna Pogrebna from Menhir Photonics will be attending Space Tech Expo Europe in Bremen, Germany, from 18-20 November 2025. Visit Europe’s largest B2B space event to discover how Menhir Photonics’ award-winning frequency comb technology can enable your next space mission.

Disclaimers: Funding awarded through the GSTP Programme (ESA Contract No. 4000146088/24/NL/KK/mdu).

Find out more information about SPARCOM and Menhir Photonics’ space-qualified products.

Search

Popular posts

- Deep-Tech Decisions: Bootstrapped Growth vs. VC Scale

- CyberRidge and Menhir Photonics: A Strategic Partnership Advancing Photonic-Layer Security

- SPARCOM: Bringing Frequency Combs to the Final Frontier

- The Engineering Vision Behind Menhir Photonics: From Quantum Curiosity to Industrial Reality

- Applied Photonics Award: Sarah Hutter Honored for Ultrabroadband Laser Breakthrough